In-Depth Pipeline Analysis with Additional Report Types

Additional reporting available from the same UHR ILI run for your pipeline inspection You rely on an ILI inspection to deliver comprehensive data about your pipeline, but informed decision making requires much more than a static set of findings — you need understanding. This is where reporting services come in. Good reporting isn’t a matter …

Additional reporting available from the same UHR ILI run for your pipeline inspection

You rely on an ILI inspection to deliver comprehensive data about your pipeline, but informed decision making requires much more than a static set of findings — you need understanding. This is where reporting services come in. Good reporting isn’t a matter of consolidating data, it’s a matter of contextualizing it. And while no pipeline analysis should be rushed, the reality is, you need reliable, actionable information as quickly as possible.

ENTEGRA® UHR ILI data analysis services are geared toward delivering timely, usable reports that make it easier for you to make operational decisions with confidence. Our standard reports are designed to provide you with a full picture of pipeline anomalies, while our optional reporting services let you dig deeper into specific issues before you break ground.

High-quality data analysis

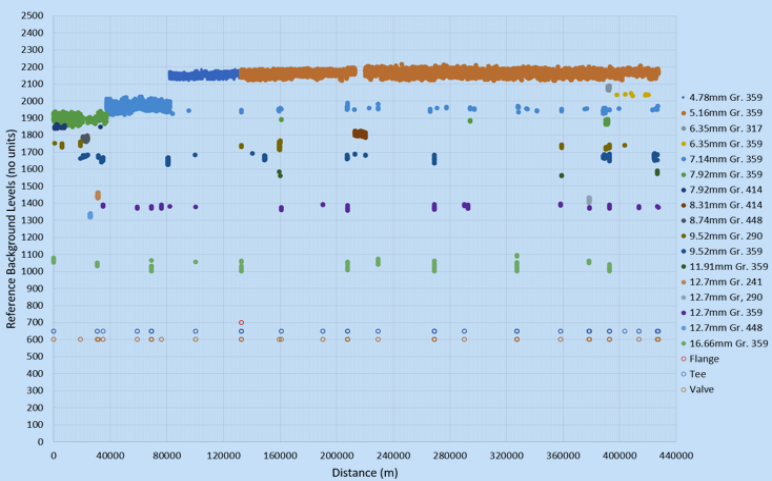

Good reporting starts with solid data analysis. First, our UHR MFL/CAL/IMU tools pull an incredibly detailed amount of data from one run. Then, ENTEGRA uses a multi-tiered approach led by our team of Level III data analysts. We combine sophisticated, proprietary automated data analysis, machine learning and human experience-based analysis to provide you with a complete understanding of pipeline issues. Our process allows us to tease out nuances in anomalies to help you prioritize issues and mitigate risks. From this analysis, we produce our standard reports which are easy to understand and actionable — with our team right there alongside you.

Reporting that sets a higher standard

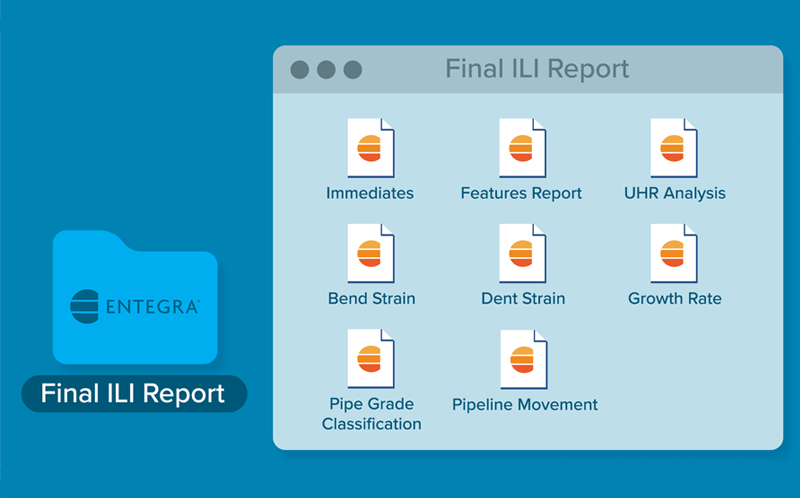

ENTEGRA focuses on a high first-run success rate because we know this makes all the difference in getting our clients the high-quality information they need in a timely fashion. Our UHR ILI system enables us to provide preliminary reports in days, allowing you to act on anomalies that could require more immediate intervention while our team works to prepare a complete final report. Our standard reports are typically delivered within 45-90 days and cover the following features, and more:

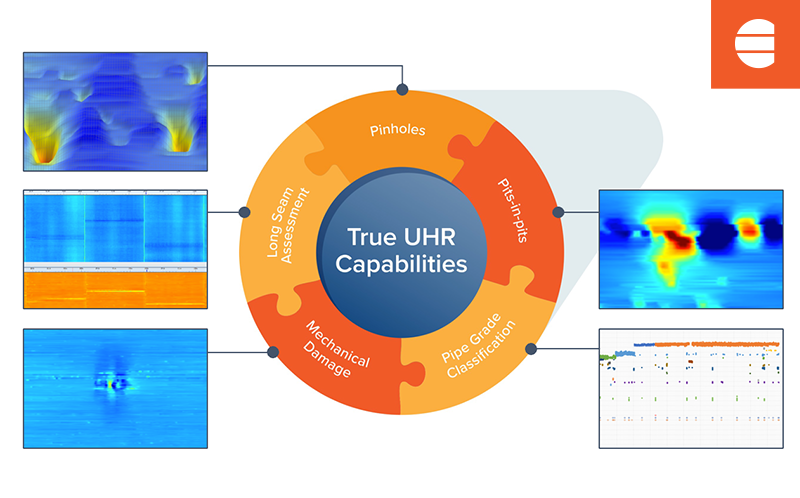

- Pinholes: ENTEGRA UHR ILI is capable of characterizing pinholes as small as 3 mm x 3 mm to reduce the risk of leaks or shutdowns.

- Complex corrosion: ENTEGRA UHR ILI can identify these anomalies when metal loss groups interact with one another or with other pipeline features. This includes reporting on pits-in-pits, or pinholes appearing inside a larger area of light metal loss, which legacy ILI technologies often miss.

- Seam welds: Seam weld pipe may contain manufacturing issues (e.g. trim) or metal loss that could affect the seam weld. ENTEGRA’s UHR data can differentiate adjacent anomalies from preferential from coincidental.

- Mechanical damage: Not all mechanical damage requires intervention. True UHR MFL in-line inspection (ILI) can differentiate gouge-type metal loss from corrosion-type metal loss, with or without any associate pipe deformation.

- Hard spots: ENTEGRA UHR ILI is uniquely equipped to detect hard spots, distinguishing size, shape and assign a Brinell value to identify those that require action.

Supplemental analyses

In cases where there are specific concerns about pipeline issues, ENTEGRA offers additional reports that provide more in-depth analysis. These reports are gathered from the same ILI data captured in the initial run, so no additional pigging is required. For these supplemental analyses, our data analysis team performs additional reviews of the relevant content from the full dataset. These analyses can be tailored to the particulars of a given pipeline and your operational needs. Options include:

Pipeline movement analysis is performed using two sets of inertial data using a high-frequency coordinate file. This helps operators identify shifts in the pipeline from natural causes, human intervention or an accident. Where movement is detected, a follow-up analysis of bend strain can identify whether the pipe is experiencing any increased stress.

Bend strain analysis provides deeper understanding of the stress and strain relationship that may be happening in areas of the pipeline. This analysis helps determine where stress is causing potentially worrisome strain on a pipe that could lead to breaking. Starting with a detailed understanding of any pipeline movement, ENTEGRA can analyze where strain may be growing, or where stress is mitigated and isn’t resulting in additional strain.

Dent strain analysis uses UHR caliper data to examine the surface geometry of dents. ENTEGRA calipers actually touch the pipe to provide detailed information on deformation shape. Through the ENTEGRA analysis process, we can identify the sharpest points of the deformation. Smooth dents are less likely to tax the pipe, whereas sharp changes may indicate an anomaly that needs more immediate attention.

Growth rate analysis examines the growth of corrosion over time. Due to factors like temperature, pressure or coating issues, not all areas of corrosion advance at the same rate. ENTEGRA compares volume, density and frequency of specific areas of corrosion with previous datasets, factoring in differences between tolerances used in prior surveys and those used in the current run. With this information, operators can focus on areas of the pipe that may be corroding at a faster rate. This lets operators instigate active control and mitigation efforts, as well as forecast areas of corrosion that may require future attention.

ILI reports that deliver detail and context add value to your operation. When your pipeline inspection reports are thorough and reliable, you can focus on action rather than interpretation. From our standard reporting offerings to our customized options, all backed by a dedicated team there to answer questions, ENTEGRA reports help you save time and increase confidence in your pipeline integrity decisions.